what term does the dairy industry now use to identify what was formerly called skim milk?

A dairy is a business enterprise established for the harvesting or processing (or both) of fauna milk – more often than not from cows or buffaloes, only also from goats, sheep, horses, or camels – for homo consumption. A dairy is typically located on a dedicated dairy farm or in a section of a multi-purpose farm (mixed subcontract) that is concerned with the harvesting of milk.

As an attributive, the word dairy refers to milk-based products, derivatives and processes, and the animals and workers involved in their product: for case dairy cattle, dairy goat. A dairy farm produces milk and a dairy manufactory processes it into a multifariousness of dairy products. These establishments constitute the global dairy manufacture, part of the food manufacture.

Terminology [edit]

Terminology differs betwixt countries. in the United States, for case, an entire dairy farm is commonly called a "dairy". The building or farm area where milk is harvested from the cow is often called a "milking parlor" or "parlor", except in the case of smaller dairies, where cows are frequently put on pasture, and commonly milked in "stanchion barns". The farm area where milk is stored in bulk tanks is known every bit the subcontract's "milk business firm". Milk is then hauled (normally past truck) to a "dairy plant", likewise referred to as a "dairy", where raw milk is further processed and prepared for commercial sale of dairy products. In New Zealand, farm areas for milk harvesting are likewise called "milking parlours", and are historically known as "milking sheds".[ citation needed ] Equally in the United states, sometimes milking sheds are referred to by their type, such as "herring bone shed" or "pit parlour". Parlour blueprint has evolved from simple barns or sheds to large rotary structures in which the workflow (throughput of cows) is very efficiently handled. In some countries, especially those with small numbers of animals being milked, the subcontract may perform the functions of a dairy institute, processing their ain milk into salable dairy products, such as butter, cheese, or yogurt. This on-site processing is a traditional method of producing specialist milk products, mutual in Europe.

In the United States a dairy tin can besides be a place that processes, distributes and sells dairy products, or a room, building or establishment where milk is stored and candy into milk products, such as butter or cheese. In New Zealand English the atypical employ of the discussion dairy most exclusively refers to a corner shop, or superette. This usage is historical as such shops were a mutual place for the public to purchase milk products.

History [edit]

Milk producing animals take been domesticated for thousands of years. Initially, they were part of the subsistence farming that nomads engaged in. Every bit the customs moved about the country, their animals accompanied them. Protecting and feeding the animals were a big part of the symbiotic relationship between the animals and the herders.

In the more recent past, people in agricultural societies owned dairy animals that they milked for domestic and local (village) consumption, a typical example of a cottage manufacture. The animals might serve multiple purposes (for example, as a draught animal for pulling a plow as a youngster, and at the end of its useful life as meat). In this case, the animals were normally milked by hand and the herd size was quite minor, so that all of the animals could be milked in less than an hour—most 10 per milker. These tasks were performed by a dairymaid (dairywoman) or dairyman. The give-and-take dairy harkens back to Eye English dayerie, deyerie, from deye (female person retainer or dairymaid) and further back to Old English dæge (kneader of bread).

With industrialization and urbanization, the supply of milk became a commercial industry, with specialized breeds of cattle beingness adult for dairy, as singled-out from beef or draught animals. Initially, more than people were employed as milkers, but it soon turned to mechanization with machines designed to do the milking.

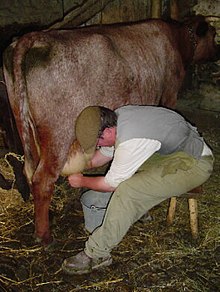

Farmer milking a cow by hand

Historically, the milking and the processing took place close together in infinite and fourth dimension: on a dairy farm. People milked the animals past hand; on farms where simply small numbers are kept, hand-milking may nonetheless be adept. Hand-milking is accomplished by grasping the teats (often pronounced tit or tits) in the mitt and expressing milk either by squeezing the fingers progressively, from the udder end to the tip, or by squeezing the teat betwixt thumb and index finger, and so moving the mitt downward from udder towards the end of the teat. The action of the paw or fingers is designed to close off the milk duct at the udder (upper) end and, by the movement of the fingers, shut the duct progressively to the tip to express the trapped milk. Each one-half or quarter of the udder is emptied i milk-duct capacity at a fourth dimension.

The stripping action is repeated, using both hands for speed. Both methods result in the milk that was trapped in the milk duct being squirted out the end into a bucket that is supported betwixt the knees (or rests on the ground) of the milker, who usually sits on a low stool.

Traditionally the cow, or cows, would stand up in the field or paddock while existence milked. Young stock, heifers, would have to be trained to remain all the same to be milked. In many countries, the cows were tethered to a post and milked.

Construction of the industry [edit]

While most countries produce their own milk products, the construction of the dairy manufacture varies in different parts of the world. In major milk-producing countries virtually milk is distributed through whole sale markets. In Ireland and Australia, for example, farmers' co-operatives own many of the large-scale processors, while in the United states many farmers and processors do business through individual contracts. In the United states of america, the country'due south 196 farmers' cooperatives sold 86% of milk in the U.S. in 2002, with 5 cooperatives accounting for half that. This was down from 2,300 cooperatives in the 1940s.[1] In developing countries, the by exercise of farmers marketing milk in their own neighborhoods is changing apace. Notable developments include considerable strange investment in the dairy manufacture and a growing part for dairy cooperatives. Output of milk is growing chop-chop in such countries and presents a major source of income growth for many farmers.[2]

As in many other branches of the food industry, dairy processing in the major dairy producing countries has go increasingly full-bodied, with fewer but larger and more efficient plants operated past fewer workers. This is notably the case in the United States, Europe, Australia and New Zealand. In 2009, charges of antitrust violations have been made confronting major dairy manufacture players in the United states of america, which critics telephone call Large Milk.[3] Another round of toll fixing charges was settled in 2016.[4]

Government intervention in milk markets was common in the 20th century. A limited antitrust exemption was created for U.S. dairy cooperatives by the Capper–Volstead Act of 1922. In the 1930s, some U.S. states adopted price controls, and Federal Milk Marketing Orders started under the Agronomical Marketing Agreement Act of 1937 and go along in the 2000s. The Federal Milk Cost Support Plan began in 1949.[1] The Northeast Dairy Compact regulated wholesale milk prices in New England from 1997 to 2001.[5]

Plants producing liquid milk and products with short shelf life, such as yogurts, creams and soft cheeses, tend to exist located on the outskirts of urban centres close to consumer markets. Plants manufacturing items with longer shelf life, such as butter, milk powders, cheese and whey powders, tend to be situated in rural areas closer to the milk supply. Most big processing plants tend to specialise in a limited range of products. Exceptionally, yet, large plants producing a broad range of products are even so mutual in Eastern Europe, a holdover from the erstwhile centralized, supply-driven concept of the market nether Communist governments.[6]

As processing plants grow fewer and larger, they tend to larn bigger, more automated and more than efficient equipment. While this technological tendency keeps manufacturing costs lower, the demand for long-distance transportation ofttimes increases the environmental bear on.[7]

Milk production is irregular, depending on cow biology. Producers must adjust the mix of milk which is sold in liquid form vs. processed foods (such equally butter and cheese) depending on changing supply and demand.[1]

Milk supply contracts [edit]

In the European Union, milk supply contracts are regulated by Article 148 of Regulation 1308/2013 - Establishing a common organisation of the markets in agronomical products and repealing Council Regulations (EEC) No 922/72, (EEC) No 234/79, (EC) No 1037/2001 and (EC) No 1234/2007, which permits member states to create a requirement for the supply of milk from a farmer to a raw milk processor to be backed by a written contract, or to ensure that the first purchaser of milk to brand a written offering to the farmer, although in this case the farmer may non exist required to enter into a contract.[viii]

Xiii EU fellow member states including French republic and Kingdom of spain have introduced laws on compulsory or mandatory written milk contracts (MWC'southward) between farmers and processors. The Scottish Authorities published an assay of the dairy supply concatenation and the awarding of mandatory written contracts across the European Wedlock in 2019, to evaluate the impact of the contracts where they have been adopted.[nine] In the UK, a voluntary code of best practice on contractual relationships in the dairy sector was agreed by manufacture during 2012: this set out minimum standards of good exercise for contracts between producers and purchasers.[10] During 2020 the UK government has undertaken a consultation exercise to decide which contractual measures, if any, would improve the resilience of the dairy manufacture for the future.[11]

The Australian government has as well introduced a mandatory dairy code of carry.[10]

Farming [edit]

When it became necessary to milk larger cows, the cows would be brought to a shed or barn that was gear up with stalls (milking stalls) where the cows could exist bars their whole life while they were milked. I person could milk more cows this way, as many as 20 for a skilled worker. Simply having cows standing about in the yard and shed waiting to exist milked is non good for the moo-cow, as she needs equally much time in the paddock grazing as is possible. It is usual to restrict the twice-daily milking to a maximum of an hr and a half each fourth dimension. It makes no difference whether one milks x or chiliad cows, the milking fourth dimension should not exceed a total of most iii hours each twenty-four hours for any moo-cow as they should be in stalls and laying downwardly equally long as possible to increase comfort which will in turn aid in milk production. A cow is physically milked for only almost x minutes a day depending on her milk letdown time and the number of milkings per day.

As herd sizes increased in that location was more need to have efficient milking machines, sheds, milk-storage facilities (vats), bulk-milk transport and shed cleaning capabilities and the ways of getting cows from paddock to shed and back.

As herd numbers increased then did the problems of animal wellness. In New Zealand two approaches to this trouble take been used. The first was improved veterinary medicines (and the government regulation of the medicines) that the farmer could use. The other was the cosmos of veterinary clubs where groups of farmers would employ a veterinarian (vet) total-time and share those services throughout the year. It was in the vet's interest to go along the animals healthy and reduce the number of calls from farmers, rather than to ensure that the farmer needed to phone call for service and pay regularly.

This daily milking routine goes on for about 300 to 320 days per year that the cow stays in milk. Some minor herds are milked once a day for about the last 20 days of the product cycle but this is non usual for large herds. If a cow is left unmilked just once she is likely to reduce milk-product virtually immediately and the residue of the season may come across her dried off (giving no milk) and still consuming feed. However, once-a-day milking is at present being practised more than widely in New Zealand for turn a profit and lifestyle reasons. This is constructive because the fall in milk yield is at to the lowest degree partially beginning past labour and cost savings from milking once per solar day. This compares to some intensive farm systems in the United States that milk three or more times per day due to higher milk yields per moo-cow and lower marginal labor costs.

Farmers who are contracted to supply liquid milk for human being consumption (as opposed to milk for processing into butter, cheese, and then on—see milk) frequently have to manage their herd and then that the contracted number of cows are in milk the twelvemonth round, or the required minimum milk output is maintained. This is done by mating cows outside their natural mating time so that the catamenia when each cow in the herd is giving maximum production is in rotation throughout the yr.

Northern hemisphere farmers who continue cows in barns almost all the year usually manage their herds to requite continuous production of milk so that they become paid all year round. In the southern hemisphere the cooperative dairying systems permit for two months on no productivity because their systems are designed to take advantage of maximum grass and milk product in the spring and because the milk processing plants pay bonuses in the dry (wintertime) season to carry the farmers through the mid-winter pause from milking. It too means that cows have a residue from milk production when they are nigh heavily pregnant. Some year-round milk farms are penalised financially for overproduction at any fourth dimension in the year by being unable to sell their overproduction at current prices.

Bogus insemination (AI) is mutual in all high-production herds in order to better the genetics of the female offspring which will be raised for replacements. AI also reduces the need for keeping potentially dangerous bulls on the farm. Male person calves are sold to be raised for beef or veal, or slaughtered due to lack of profitability.[12] A moo-cow will calve or freshen almost once a year, until she is culled because of failing production, infertility or other health problems. Then the cow will be sold, most often going to slaughter.[13]

Industrial processing [edit]

A Fonterra cooperative dairy manufactory in Australia

Dairy plants procedure the raw milk they receive from farmers so as to extend its marketable life. Ii chief types of processes are employed: rut treatment to ensure the condom of milk for human consumption and to lengthen its shelf-life, and dehydrating dairy products such equally butter, hard cheese and milk powders so that they can be stored.

Cream and butter [edit]

Today, milk is separated past huge machines in bulk into foam and skim milk. The foam is processed to produce various consumer products, depending on its thickness, its suitability for culinary uses and consumer demand, which differs from place to place and state to state.

Some milk is dried and powdered, some is condensed (past evaporation) mixed with varying amounts of carbohydrate and canned. Nearly cream from New Zealand and Australian factories is made into butter. This is washed by churning the cream until the fat globules coalesce and form a monolithic mass. This butter mass is washed and, sometimes, salted to improve keeping qualities. The residual buttermilk goes on to further processing. The butter is packaged (25 to 50 kg boxes) and chilled for storage and auction. At a afterwards stage these packages are broken downwardly into home-consumption sized packs.

Skimmed milk [edit]

The product left after the cream is removed is chosen skim, or skimmed, milk. To make a consumable liquid a portion of cream is returned to the skim milk to make depression fatty milk (semi-skimmed) for human consumption. By varying the amount of foam returned, producers can brand a diversity of low-fatty milks to suit their local market place. Whole milk is also made by adding foam back to the skim to form a standardized production. Other products, such as calcium, vitamin D, and flavouring, are also added to entreatment to consumers.

Casein [edit]

Casein is the predominant phosphoprotein institute in fresh milk. Information technology has a very wide range of uses from existence a filler for human foods, such every bit in ice cream, to the manufacture of products such equally fabric, adhesives, and plastics.

Cheese [edit]

Cheese is another product made from milk. Whole milk is reacted to class curds that tin can be compressed, processed and stored to course cheese. In countries where milk is legally allowed to be processed without pasteurization, a wide range of cheeses can exist made using the leaner institute naturally in the milk. In most other countries, the range of cheeses is smaller and the use of bogus cheese curing is greater. Whey is also the byproduct of this process. Some people with lactose intolerance are surprisingly able to eat certain types of cheese. This is because some traditionally made hard cheeses, and soft ripened cheeses may create less reaction than the equivalent corporeality of milk considering of the processes involved. Fermentation and higher fat content contribute to bottom amounts of lactose. Traditionally made Emmental or Cheddar might contain x% of the lactose found in whole milk. In addition, the aging methods of traditional cheeses (sometimes over two years) reduce their lactose content to practically nothing.[xiv] Commercial cheeses, however, are oftentimes manufactured by processes that practice not have the aforementioned lactose-reducing properties. Ageing of some cheeses is governed past regulations;[15] in other cases there is no quantitative indication of caste of ageing and concomitant lactose reduction, and lactose content is non commonly indicated on labels.

Whey [edit]

In before times, whey or milk serum was considered to be a waste material product and information technology was, mostly, fed to pigs as a user-friendly means of disposal. Beginning about 1950, and mostly since about 1980, lactose and many other products, mainly food additives, are fabricated from both casein and cheese whey.

Yogurt [edit]

Yogurt (or yoghurt) making is a procedure similar to cheese making, only the procedure is arrested before the curd becomes very hard.

Milk powders [edit]

Milk is besides processed by diverse drying processes into powders. Whole milk, skim milk, buttermilk, and whey products are dried into a powder form and used for human being and animal consumption. The principal difference betwixt production of powders for human or for animal consumption is in the protection of the process and the product from contamination. Some people beverage milk reconstituted from powdered milk, because milk is about 88% water and it is much cheaper to transport the stale product.

Other milk products [edit]

Kumis is produced commercially in Central Asia. Although traditionally made from mare's milk, modern industrial variants may use cow's milk. In India, which produces 22% of global milk production (every bit at 2018), a range of traditional milk-based products are produced commercially.

Milking [edit]

Originally, milking and processing took place on the dairy farm itself. Subsequently, cream was separated from the milk past machine on the farm, and transported to a factory to be made into butter. The skim milk was fed to pigs. This allowed for the high cost of transport (taking the smallest volume loftier-value product), archaic trucks and the poor quality of roads. Only farms close to factories could afford to accept whole milk, which was essential for cheesemaking in industrial quantities, to them.

Originally milk was distributed in 'pails', a lidded bucket with a handle. These proved impractical for transport past road or track, and so the milk churn was introduced, based on the tall conical shape of the butter churn. Later big railway containers, such as the British Railway Milk Tank Wagon were introduced, enabling the transport of larger quantities of milk, and over longer distances.

The development of refrigeration and improve route ship, in the late 1950s, has meant that nearly farmers milk their cows and only temporarily store the milk in large refrigerated bulk tanks, from where information technology is later transported by truck to central processing facilities.

In many European countries, especially the United kingdom of great britain and northern ireland, milk is then delivered direct to customers' homes past a milk float.

In the U.s., a dairy cow produced nigh 5,300 pounds (2,400 kg) of milk per year in 1950, while the boilerplate Holstein cow in 2019 produces more than 23,000 pounds (10,000 kg) of milk per year.[xvi]

Milking machines [edit]

The milking machine extracts milk from all teats.

Milking machines are used to harvest milk from cows when transmission milking becomes inefficient or labour-intensive. 1 early model was patented in 1907.[17] The milking unit is the portion of a milking machine for removing milk from an udder. It is made upwards of a claw, four teatcups, (Shells and rubber liners) long milk tube, long pulsation tube, and a pulsator. The claw is an associates that connects the short pulse tubes and brusque milk tubes from the teatcups to the long pulse tube and long milk tube. (Cluster associates) Claws are commonly made of stainless steel or plastic or both. Teatcups are composed of a rigid outer shell (stainless steel or plastic) that holds a soft inner liner or inflation. Transparent sections in the crush may allow viewing of liner collapse and milk period. The annular space between the shell and liner is called the pulse chamber.

Milking machines work in a manner that is unlike from hand milking or dogie suckling. Continuous vacuum is practical inside the soft liner to massage milk from the teat past creating a pressure departure across the teat canal (or opening at the cease of the teat). Vacuum also helps go along the machine attached to the cow. The vacuum practical to the teat causes congestion of teat tissues (aggregating of blood and other fluids). Atmospheric air is admitted into the pulsation sleeping room nigh once per second (the pulsation rate) to allow the liner to collapse around the end of teat and salvage congestion in the teat tissue. The ratio of the time that the liner is open up (milking phase) and airtight (rest phase) is called the pulsation ratio.

The four streams of milk from the teatcups are usually combined in the claw and transported to the milkline, or the collection saucepan (normally sized to the output of one cow) in a single milk hose. Milk is then transported (manually in buckets) or with a combination of airflow and mechanical pump to a primal storage vat or bulk tank. Milk is refrigerated on the farm in most countries either past passing through a heat-exchanger or in the bulk tank, or both.

The photo to the right shows a bucket milking organization with the stainless steel saucepan visible on the far side of the cow. The two rigid stainless steel teatcup shells applied to the front end two quarters of the udder are visible. The top of the flexible liner is visible at the top of the shells as are the short milk tubes and brusk pulsation tubes extending from the lesser of the shells to the hook. The bottom of the claw is transparent to allow observation of milk flow. When milking is completed the vacuum to the milking unit is shut off and the teatcups are removed.

Milking machines go along the milk enclosed and safe from external contamination. The interior 'milk contact' surfaces of the machine are kept clean by a manual or automatic washing procedures implemented after milking is completed. Milk contact surfaces must comply with regulations requiring food-form materials (typically stainless steel and special plastics and rubber compounds) and are easily cleaned.

Virtually milking machines are powered past electricity just, in case of electric failure, there can be an alternative ways of motive power, often an internal combustion engine, for the vacuum and milk pumps.

Milking shed layouts [edit]

Bond-style sheds [edit]

This type of milking facility was the beginning development, after open up-paddock milking, for many farmers. The building was a long, narrow, lean-to shed that was open along one long side. The cows were held in a g at the open side and when they were almost to be milked they were positioned in one of the bails (stalls). Usually the cows were restrained in the bond with a breech concatenation and a rope to restrain the outer back leg. The cow could not movement near excessively and the milker could await not to be kicked or trampled while sitting on a (three-legged) stool and milking into a saucepan. When each cow was finished she backed out into the yard again. The UK bond, initially developed by Wiltshire dairy farmer Arthur Hosier, was a half dozen standing mobile shed with steps that the cow mounted, so the herdsman didn't take to curve so low. The milking equipment was much as today, a vacuum from a pump, pulsators, a claw-slice with pipes leading to the 4 shells and liners that stimulate and suck the milk from the teat. The milk went into churns, via a cooler.

Every bit herd sizes increased a door was gear up into the front of each bond and then that when the milking was washed for any cow the milker could, after undoing the leg-rope and with a remote link, open the door and allow her to exit to the pasture. The door was closed, the next moo-cow walked into the bail and was secured. When milking machines were introduced bails were prepare in pairs so that a cow was being milked in one paired bail while the other could exist prepared for milking. When one was finished the automobile's cups are swapped to the other cow. This is the same every bit for Swingover Milking Parlours as described below except that the cups are loaded on the udder from the side. As herd numbers increased information technology was easier to double-upwardly the loving cup-sets and milk both cows simultaneously than to increase the number of bails. Near 50 cows an hour tin can exist milked in a shed with 8 bails by 1 person. Using the same teat cups for successive cows has the danger of transmitting infection, mastitis, from 1 moo-cow to another. Some farmers accept devised their own ways to disinfect the clusters between cows.

Herringbone milking parlours [edit]

In herringbone milking sheds, or parlours, cows enter, in single file, and line up about perpendicular to the central aisle of the milking parlour on both sides of a central pit in which the milker works (y'all can visualise a fishbone with the ribs representing the cows and the spine beingness the milker'due south working surface area; the cows face outward). Afterwards washing the udder and teats the cups of the milking machine are applied to the cows, from the rear of their hind legs, on both sides of the working area. Large herringbone sheds can milk up to 600 cows efficiently with two people.

Swingover milking parlours [edit]

Swingover parlours are the aforementioned every bit herringbone parlours except they have only one set of milking cups to be shared between the two rows of cows, equally one side is being milked the cows on the other side are moved out and replaced with unmilked ones. The advantage of this system is that it is less costly to equip, however information technology operates at slightly meliorate than half-speed and one would not normally attempt to milk more than than well-nigh 100 cows with one person.

80-stand rotary dairy that is fully computerised and records milk production

Rotary milking sheds [edit]

Rotary milking sheds (also known equally Rotary milking parlor) consist of a turntable with about 12 to 100 individual stalls for cows around the outer edge. A "good" rotary will be operated with 24–32 (~48–50+) stalls by one (2) milkers. The turntable is turned by an electrical-motor drive at a rate that one plough is the time for a moo-cow to be milked completely. Equally an empty stall passes the entrance a cow steps on, facing the heart, and rotates with the turntable. The next cow moves into the next vacant stall and and then on. The operator, or milker, cleans the teats, attaches the cups and does any other feeding or whatever husbanding operations that are necessary. Cows are milked as the platform rotates. The milker, or an automatic device, removes the milking auto cups and the cow backs out and leaves at an exit just before the entrance. The rotary system is capable of milking very large herds—over a g cows.

Automated milking sheds [edit]

Automatic milking or 'robotic milking' sheds tin can be seen in Australia, New Zealand, the U.S., Canada, and many European countries. Current automatic milking sheds use the voluntary milking (VM) method. These allow the cows to voluntarily present themselves for milking at any fourth dimension of the day or dark, although repeat visits may be limited past the farmer through computer software. A robot arm is used to clean teats and apply milking equipment, while automatic gates straight cow traffic, eliminating the demand for the farmer to be present during the process. The entire process is figurer controlled.[18]

Supplementary accessories in sheds [edit]

Farmers soon realised that a milking shed was a good place to feed cows supplementary foods that overcame local dietary deficiencies or added to the cows' wellbeing and product. Each bail might have a box into which such feed is delivered as the cow arrives and so that she is eating while being milked. A computer can read the eartag of each animal to ration the right individual supplement. A close alternative is to utilize 'out-of-parlour-feeders', stalls that respond to a transponder around the cow's neck that is programmed to provide each cow with a supplementary feed, the quantity dependent on her product, stage in lactation, and the benefits of the master ration

The holding yard at the entrance of the shed is important as a means of keeping cows moving into the shed. Most yards have a powered gate that ensures that the cows are kept close to the shed.

Water is a vital commodity on a dairy subcontract: cows drink about twenty gallons (fourscore litres) a day, sheds need h2o to cool and clean them. Pumps and reservoirs are common at milking facilities. Water can be warmed by heat transfer with milk.

Temporary milk storage [edit]

Milk coming from the cow is transported to a nearby storage vessel by the airflow leaking effectually the cups on the cow or by a special "air inlet" (5-10 L/min free air) in the claw. From there it is pumped past a mechanical pump and cooled by a heat exchanger. The milk is then stored in a large vat, or bulk tank, which is commonly refrigerated until collection for processing.

Waste product disposal [edit]

In countries where cows are grazed exterior year-circular, there is lilliputian waste disposal to deal with. The about full-bodied waste product is at the milking shed, where the beast waste material may be liquefied (during the h2o-washing process) or left in a more solid form, either to be returned to be used on farm basis as organic fertilizer.[xix]

In the associated milk processing factories, most of the waste is washing water that is treated, usually by composting, and spread on subcontract fields in either liquid or solid form. This is much different from half a century agone, when the main products were butter, cheese and casein, and the rest of the milk had to be tending of as waste (sometimes as fauna feed).[20]

In dairy-intensive areas, diverse methods have been proposed for disposing of large quantities of milk. Large awarding rates of milk onto land, or disposing in a pigsty, is problematic as the balance from the decomposing milk will block the soil pores and thereby reduce the water infiltration rate through the soil contour. Every bit recovery of this effect tin can take time, whatever land-based awarding needs to be well managed and considered.[21] Other waste material milk disposal methods ordinarily employed include solidification and disposal at a solid waste landfill, disposal at a wastewater handling plant, or belch into a sanitary sewer.[22]

Associated diseases [edit]

Dairy products manufactured under unsanitary or unsuitable conditions have an increased run a risk of containing leaner. Proper sanitation practices help to reduce the rate of bacterial contagion, and pasteurization greatly decreases the amount of contaminated milk that reaches the consumer. Many countries take required regime oversight and regulations regarding dairy production, including requirements for pasteurization.

- Leptospirosis is an infection that can be transmitted to people who piece of work in dairy production through exposure to urine or to contaminated water or soil.[23] [24]

- Cowpox is a virus that today is rarely plant in either cows or humans. It is a historically important affliction, as it led to the first vaccination against the at present eradicated smallpox.

- Tuberculosis is able to be transmitted from cattle mainly via milk products that are unpasteurised. The disease has been eradicated from many countries by testing for the disease and culling suspected animals.

- Brucellosis is a bacterial disease transmitted to humans by dairy products and direct animal contact. Brucellosis has been eradicated from certain countries by testing for the disease and alternative suspected animals.

- Listeria is a bacterial disease associated with unpasteurised milk, and tin affect some cheeses made in traditional ways. Careful observance of the traditional cheesemaking methods achieves reasonable protection for the consumer.

- Crohn'due south disease has been linked to infection with the bacterium M. paratuberculosis,[25] [26] [27] [28] [29] which has been found in pasteurized retail milk in the UK and the USA.[30] M. paratuberculosis causes a similar disorder, Johne'south disease, in livestock.

Animal rights [edit]

A portion of the population,[31] including vegans and many Jains, object to dairy production as unethical, cruel to animals, and environmentally deleterious. They do not consume dairy products. They country that cattle suffer nether conditions employed by the dairy manufacture.[32] [33]

Beast rights scholars consider dairy as function of the animate being–industrial circuitous. Co-ordinate to Kathleen Stachowski, the brute–industrial complex "naturalizes the human being every bit a consumer of other animals," whose enormity includes "its long reach into our lives, and how well it has washed its job normalizing brutality toward the animals whose very being is forgotten."[34] She states that the corporate dairy manufacture, the government, and schools forms the animal–industrial complex troika of immense influence, which hides from the public's view the animal rights violations and cruelties happening within the dairy industry.[34] Stachowski besides states that the troika "hijacks" schoolchildren by promoting milk in the Thousand-12 diet education curriculum and making them "eat the products of industrial animate being product."[34]

Bovine growth hormone [edit]

In 1937, it was found that bovine somatotropin (BST or bovine growth hormone) would increase the yield of milk. Several pharmaceutical companies adult commercial rBST products and they take been approved for use in the U.S., United mexican states, Brazil, India, Russia, and at least ten others. The Earth Health Organization, and others have stated that dairy products and meat from BST-treated cows are safe for homo consumption. Nevertheless, based on negative fauna welfare furnishings,[35] rBST has not been allowed in Canada, Australia, New Zealand, Japan, State of israel, or the Eu since 2000 – and in the U.S. has lost popularity due to consumer demands for rBST-free cows,[36] [37] with only virtually 17% of all cows in America now receiving rBST.[38]

Run across too [edit]

- Dairy product

- Dairy cattle

- Animal rights

- Holstein Friesian cattle

- Milk car

References [edit]

- ^ a b c "Cooperatives in the Dairy Industry". Cooperative Information, Report 1, Section xvi (PDF). United States Section of Agriculture, Rural Evolution. September 2005. Archived from the original (PDF) on 2010-x-12.

- ^ FAO, Milk for Health and Wealth, FAO, Rome, 2009

- ^ Independent Farmers Feel Squeezed By Milk Dare Archived 2011-03-xi at the Wayback Machine past John Burnett. All Things Considered, National Public Radio. 20 Baronial 2009.

- ^ Lisa Rathke (2016-06-08). "Judge approves $50m settlement to Northeast dairy farmers". Bostonglobe.com. Archived from the original on 2016-08-xix.

- ^ "Monthly Compact, Federal Order #1, and Over-Guild Prices for Class I Milk Since the Compact Regulation Took Upshot in July of 1997". Northeast Dairy Meaty Commission. Archived from the original on 2009-07-03. Retrieved 2009-09-xv .

- ^ Field, Thomas; Taylor, Robert (2008). Scientific subcontract creature product: an introduction to creature science. Upper Saddle River, NJ: Pearson Prentice Hall. ISBN978-8120343986.

- ^ Cleaner Production Assessment in Dairy Processing Archived 2009-02-14 at the Wayback Machine, by COWI Consulting Engineers and Planners, United nations Environs Programme Partition of Technology, Industry, and Economics, Denmark Miljøstyrelsen. Published by UNEP/Earthprint, 2000 (ISBN 9789280718423). Text at Agrifood Forum - Publications - Downloads - Sector Guides - Index.

- ^ European Union, Regulation (EU) No 1308/2013 of the European Parliament and of the Quango of 17 December 2013 establishing a common arrangement of the markets in agricultural products and repealing Quango Regulations (EEC) No 922/72, (EEC) No 234/79, (EC) No 1037/2001 and (EC) No 1234/2007, Article 148 published xx December 2013, accessed 25 September 2020

- ^ Scottish Regime, Dairy contracts in European countries: enquiry, published xix Nov 2019, accessed 7 October 2020

- ^ a b DEFRA, Contractual relationships in the United kingdom dairy industry, published 24 June 2020, accessed 7 Oct 2020

- ^ DEFRA, Consultation: Contractual relationships in the UK dairy manufacture, June 2020, accessed vii Oct 2020, p. 6

- ^ "What happens to bobby calves? – RSPCA Knowledgebase". Retrieved 2020-12-08 .

- ^ "Archived re-create". Archived from the original on 2018-02-xx. Retrieved 2018-02-xix .

{{cite web}}: CS1 maint: archived copy as title (link) - ^ "DairyGood.org | Home". Ilovecheese.com. Archived from the original on 2013-07-xxx. Retrieved 2014-07-17 .

- ^ "Example of cheese regulations: "Due west Country Farmhouse Cheddar" must be aged for 9 months". Farmhousecheesemakers.com. Archived from the original on 2014-07-11. Retrieved 2014-07-17 .

- ^ O'Hagan, Maureen (2019-06-xix). "From Two Bulls, ix Million Dairy Cows". Undark Magazine. Archived from the original on 2019-06-19. Retrieved 2019-06-20 .

- ^ Hearst Magazines (August 1907). Popular Mechanics. Hearst Magazines. p. 868.

- ^ "Robotic dairy at Winnindoo, Victoria, Australia". Archived from the original on 2007-09-23.

- ^ "Surface irrigation systems for treating milk house wastewater : Dairy Extension : Academy of Minnesota Extension". Extension.umn.edu. Archived from the original on 2017-09-xv. Retrieved 20 November 2017.

- ^ Bloodgood, Don E. (20 Nov 2017). "Milk Waste Disposal". Sewage Works Journal. 20 (four): 695–706. JSTOR 25030895.

- ^ "Waste matter Direction". Environmental All-time Practice Guidelines (PDF). Dairy Catch. Archived from the original (PDF) on 2011-02-20. Retrieved 2010-10-07 .

- ^ "Fact Canvass: Proper Disposal of Milk Waste" (PDF). Indiana Department of Ecology Management. Archived from the original (PDF) on 2015-09-24. Retrieved 2014-06-07 .

- ^ "Leptospirosis in Cattle". National Animal Illness Information Service (UK). Archived from the original on 2014-06-19. Retrieved 2014-06-07 .

- ^ "Causes of leptospirosis". National Health Service (Britain). Archived from the original on 2014-05-12. Retrieved 2014-06-07 .

- ^ Hermon-Taylor, John (2009-07-14). "Mycobacterium avium subspecies paratuberculosis, Crohn's disease and the Doomsday scenario". Gut Pathogens. BioMed Central. 1 (15): 15. doi:10.1186/1757-4749-ane-fifteen. PMC2718892. PMID 19602288.

- ^ Uzoigwe JC; Khaitsa ML; Gibbs PS (October 2007). "Epidemiological evidence for Mycobacterium avium subspecies paratuberculosis as a crusade of Crohn'due south affliction". Epidemiol. Infect. 135 (7): 1057–68. doi:10.1017/S0950268807008448. PMC2870686. PMID 17445316.

- ^ Naser SA; Collins MT (December 2005). "Contend on the lack of evidence of Mycobacterium avium subsp. paratuberculosis in Crohn's disease". Inflamm. Bowel Dis. xi (12): 1123. doi:ten.1097/01.MIB.0000191609.20713.ea. PMID 16306778.

- ^ Glubb DM; Gearry RB; Barclay ML; Roberts RL; Pearson J; Keenan JI; McKenzie J; Bentley RW (2011). "NOD2 and ATG16L1 polymorphisms affect monocyte responses in Crohn'south disease". World Periodical of Gastroenterology. 17 (23): 2829–37. doi:ten.3748/wjg.v17.i23.2829 (inactive 28 February 2022). PMC3120942. PMID 21734790.

{{cite journal}}: CS1 maint: DOI inactive equally of Feb 2022 (link) - ^ Lalande JD; Behr Thousand. "NOD2 MEDIATES HOST RESISTANCE TO MYCOBACTERIUM AVIUM PARATUBERCULOSIS INFECTION" (PDF). Paratuberculosos.info. McGill University. Archived from the original (PDF) on 19 February 2013. Retrieved twenty November 2017.

- ^ Ellingson JL; Anderson JL; Koziczkowski JJ; et al. (May 2005). "Detection of viable Mycobacterium avium subsp. paratuberculosis in retail pasteurized whole milk past 2 culture methods and PCR". J. Food Prot. Journal of Food Protection, United states of america. 68 (five): 966–72. doi:10.4315/0362-028x-68.5.966. PMID 15895728.

- ^ Iacobbo, K., & Iacobbo, One thousand. (2006). Vegetarians and vegans in America today. Greenwood Publishing Group.

- ^ David J. Wolfson (2013-06-04). "Beyond the Law: Agribusiness and the Systemic Abuse of Animals Raised for Nutrient or Food Production, two ANIMAL 50. 123-154 (1996)". National Agronomical Police Eye. Archived from the original on 2018-03-10. Retrieved 2020-03-13 .

- ^ "Vache a lait Dix Mythes de lindustrie Laitiere". Archived from the original on 2013-09-21. Retrieved 2014-05-19 .

- ^ a b c Stachowski, Kathleen (12 June 2012). "The Animal-Industrial Complex: The Monster in Our Midst". Britannica.com. Encyclopaedia Britannica. Retrieved x August 2021.

If the idea of an beast industrial circuitous seemed a bit outlandish—maybe even a little paranoid—to anyone a few paragraphs back, possibly now? … non so much.

- ^ Study on Beast Welfare Aspects of the Utilise of Bovine Somatotrophin (PDF). The Scientific Committee on Brute Health and Animal Welfare, European Spousal relationship. ten March 1999. Archived from the original (PDF) on four September 2008. Retrieved sixteen January 2008.

- ^ "Safeway milk free of bovine hormone". Seattle Mail-Intelligencer. Associated Press. 22 January 2007. Retrieved 4 April 2008.

- ^ "Statement and Q&A-Starbucks Completes its Conversion – All U.S. Visitor-Operated Stores Use Dairy Sourced Without the Use of rBGH". Starbucks Corporation. Archived from the original on 29 March 2008. Retrieved four April 2008.

- ^ Foundation, GRACE Communications. "rBGH". GRACE Communications Foundation. Archived from the original on 25 January 2018. Retrieved 20 November 2017.

Farther reading [edit]

- Fuquay, John W. ed. Encyclopedia of Dairy Sciences (2nd Edition, four vol 2011), comprehensive coverage

- Jay, J. M. (1992). Modern Food Microbiology; 4th edition. New York: Chapman & Hall. pp. 237–ix.

- Lampe, Markus, and Paul Precipitous. A State of Milk and Butter: How Elites Created the Modernistic Danish Dairy Industry (U of Chicago Press, 2018) online review

- Potter, North. N. & J. H. Hotchkiss. (1995). Food Science; fifth Edition. New York: Chapman & Hall. pp. 279–315.

- Swasigood, H. E. (1985). "Characteristics of Edible Fluids of Fauna Origin: Milk." In Food Chemistry; 2nd edition. Revised and Expanded. O. R. Fennema, Ed. New York: Marcel Dekker, Inc. pp. 791–827.

- Doug Reinemann (July xviii, 2018). "Milking Machines:The Beginning 100 Years". pbswisconsin.org . Retrieved June 10, 2021.

- Wolfson, D. J. (1996). "Beyond the police force: Agribusiness and the systemic abuse of animals raised for food or food production". Animal Law. two: 123.

- Fream, William (1911). . Encyclopædia Britannica. Vol. 7 (11th ed.). pp. 737–761.

External links [edit]

-

Media related to Dairying at Wikimedia Commons

Media related to Dairying at Wikimedia Commons

johnsonhatecrable.blogspot.com

Source: https://en.wikipedia.org/wiki/Dairy

0 Response to "what term does the dairy industry now use to identify what was formerly called skim milk?"

Post a Comment